-40%

Tyco/PPM Quad 12mm Tape Peeler Upgrade Rollers - Solid Plastic Gears

$ 7.91

- Description

- Size Guide

Description

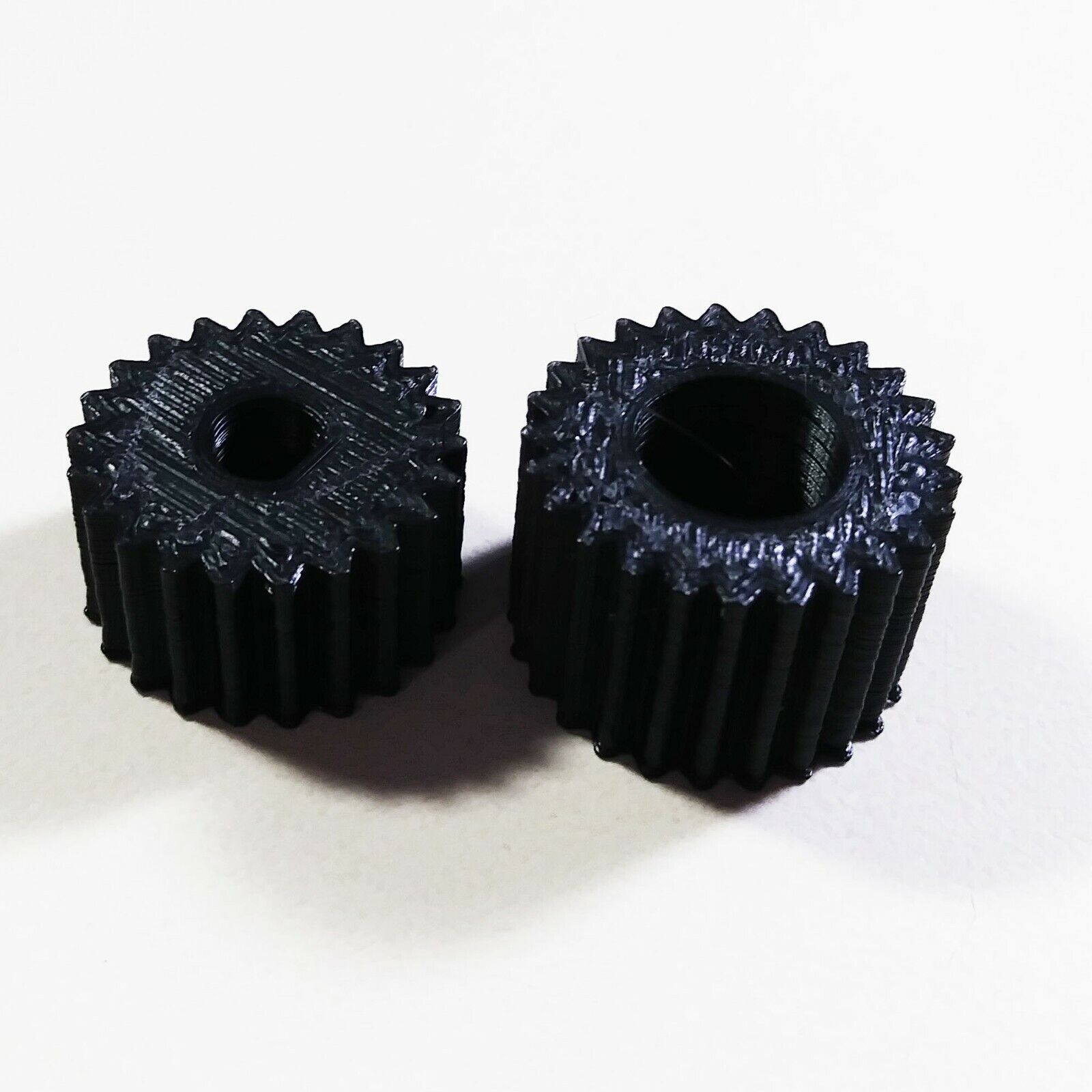

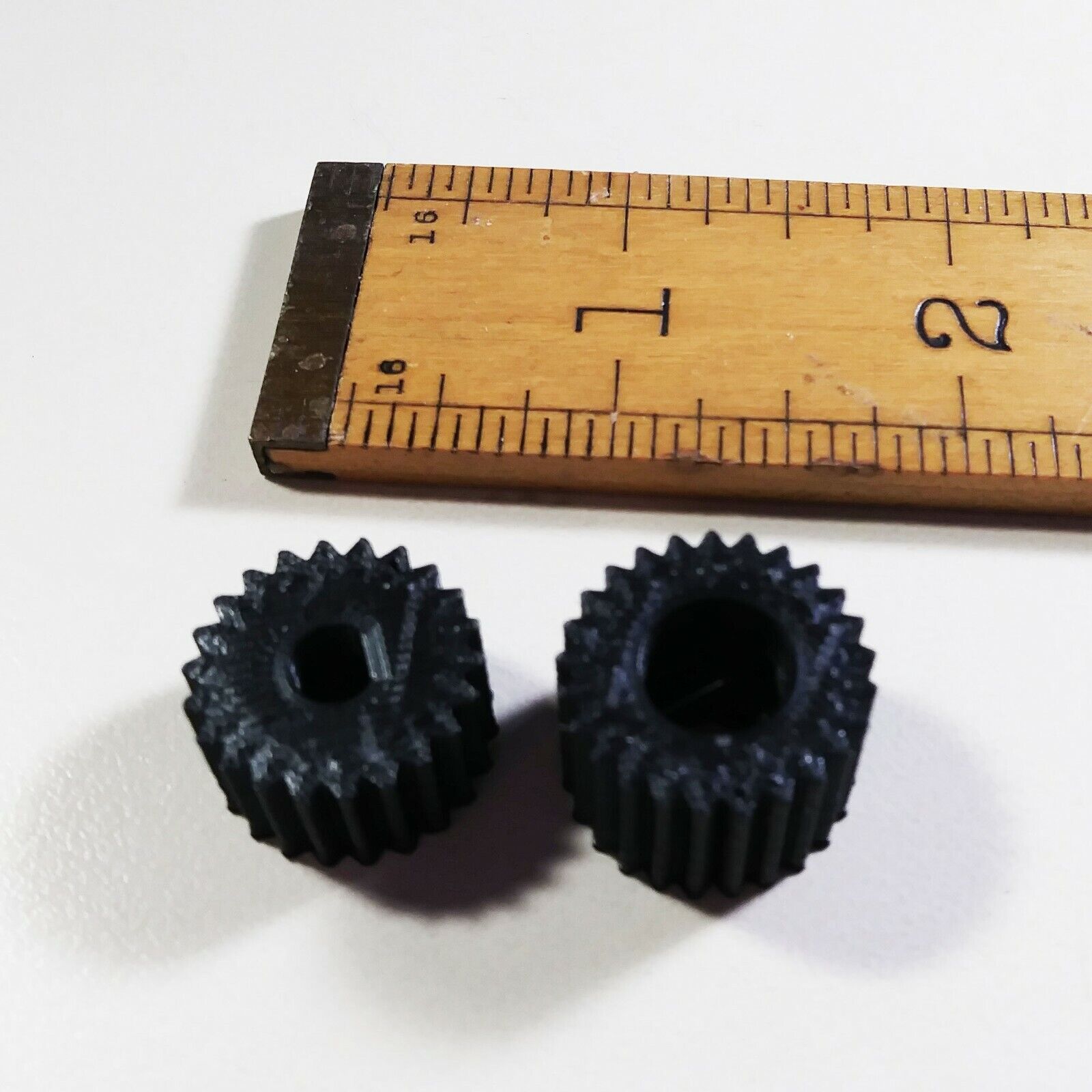

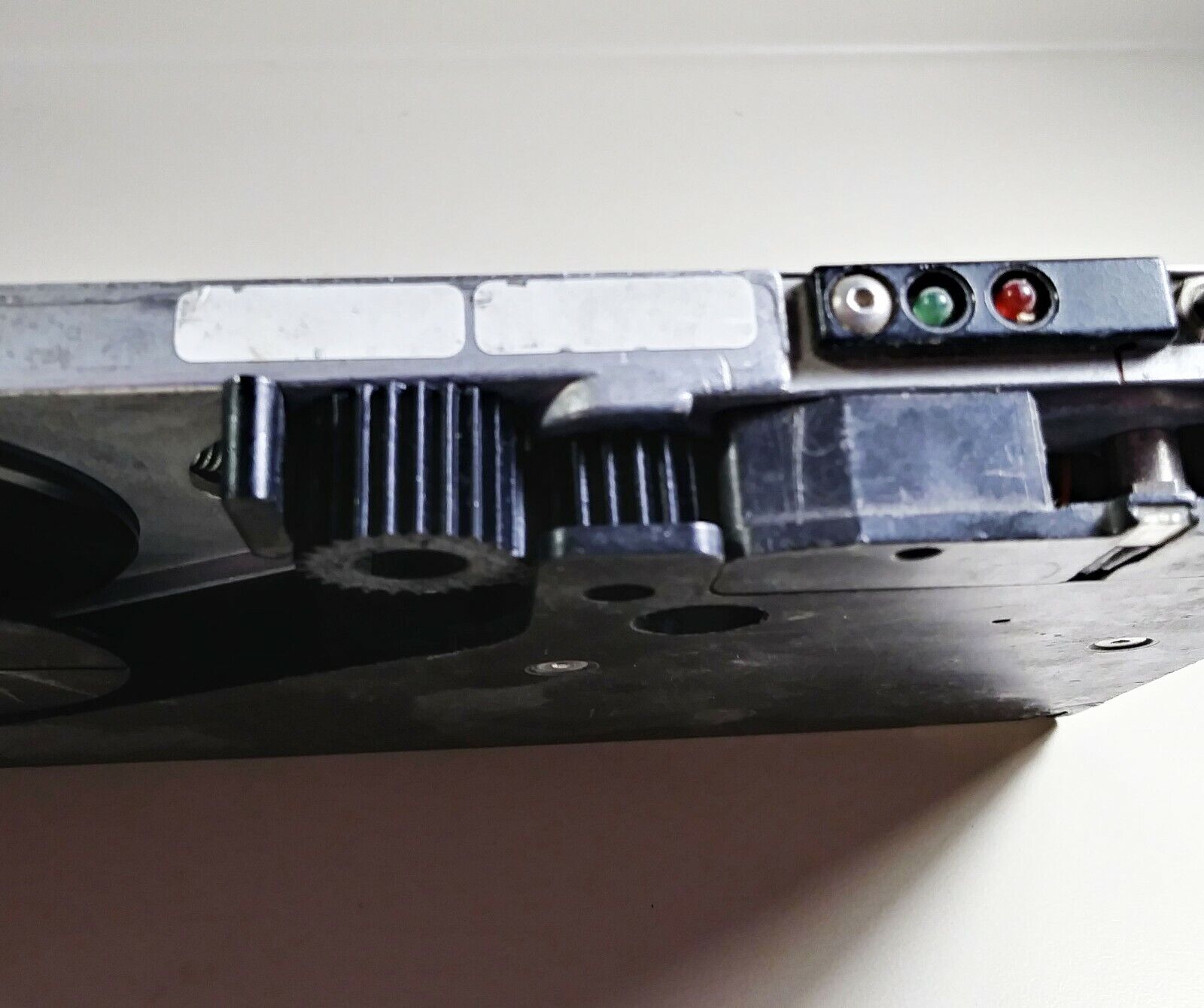

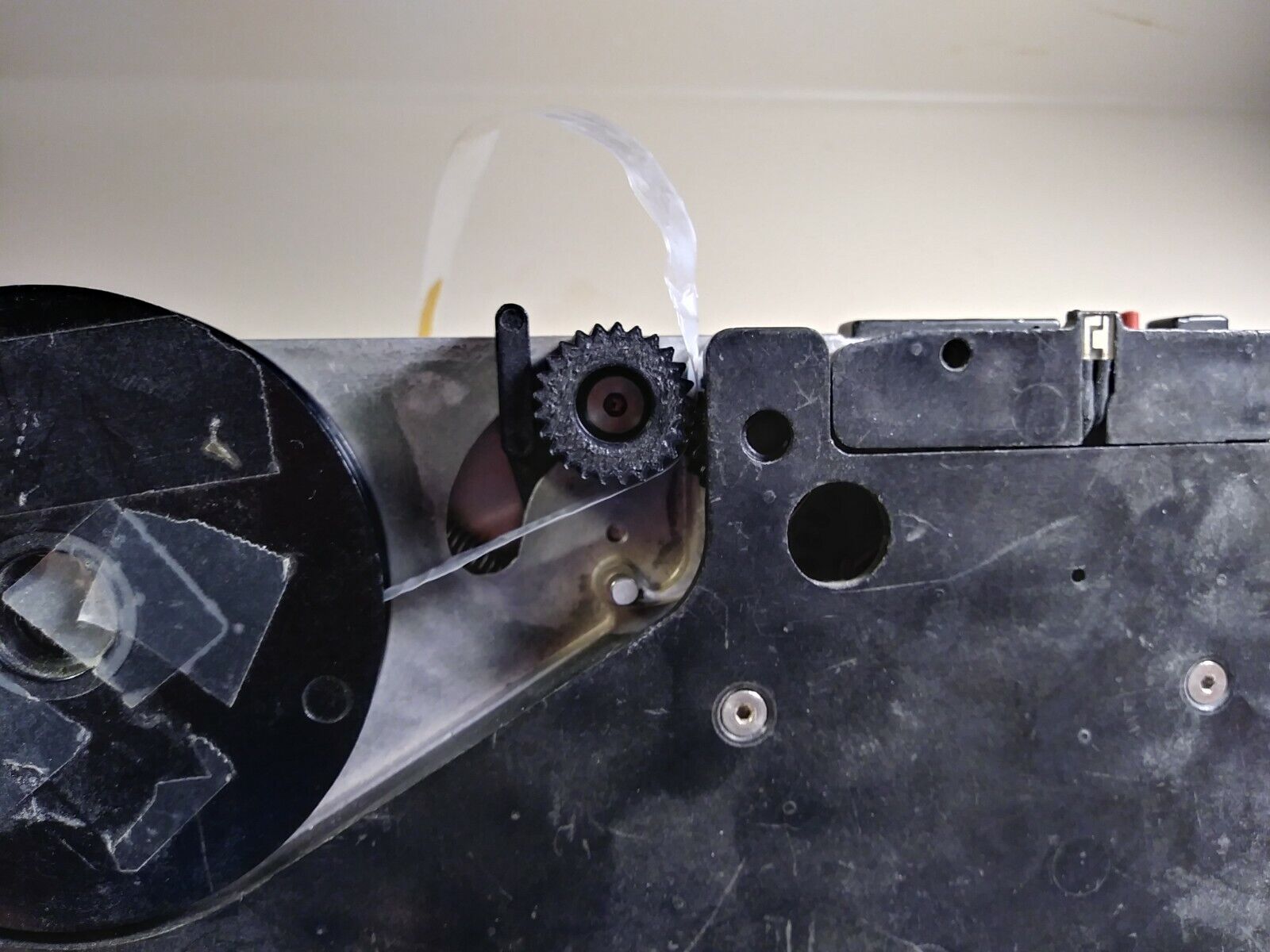

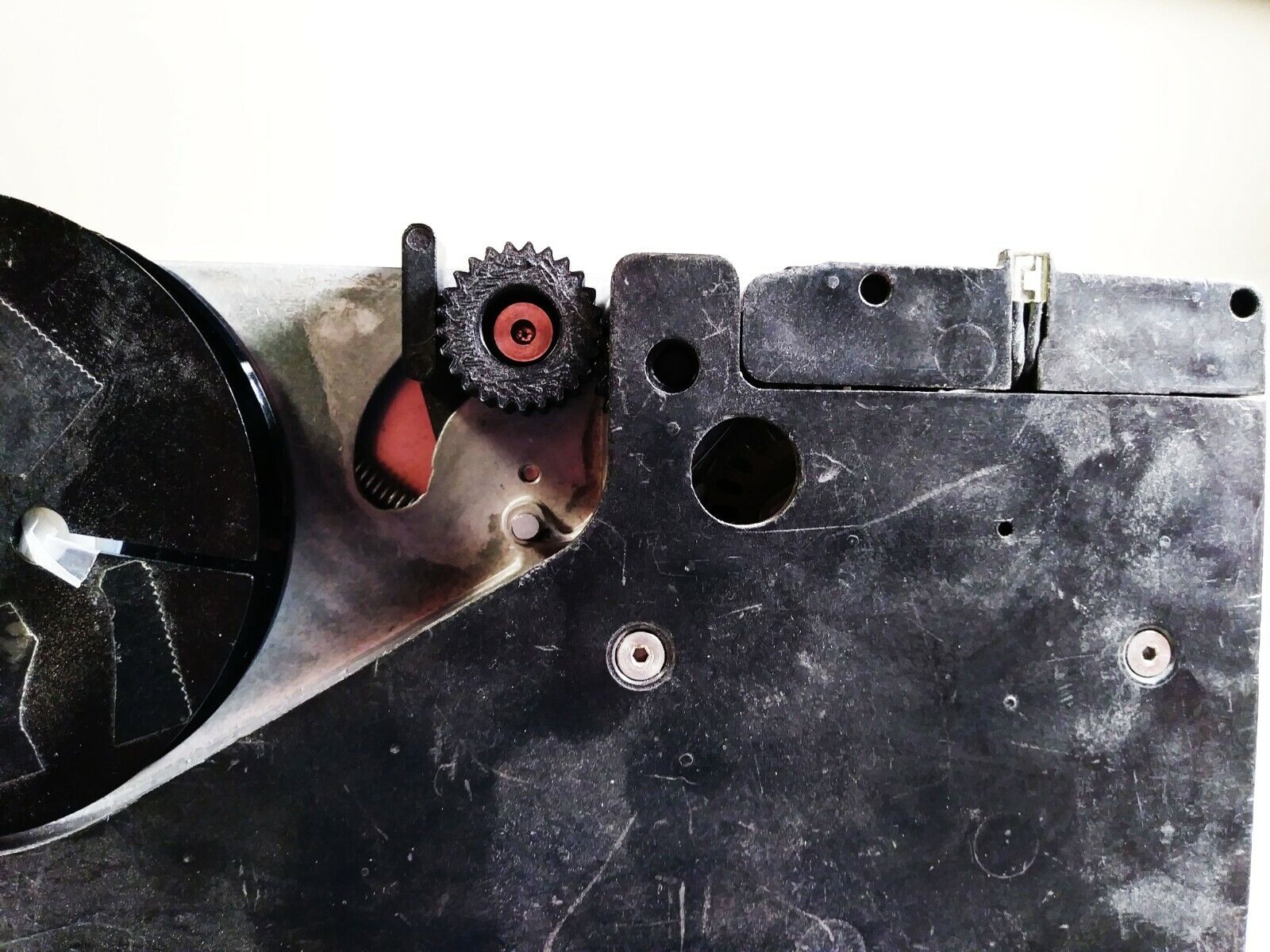

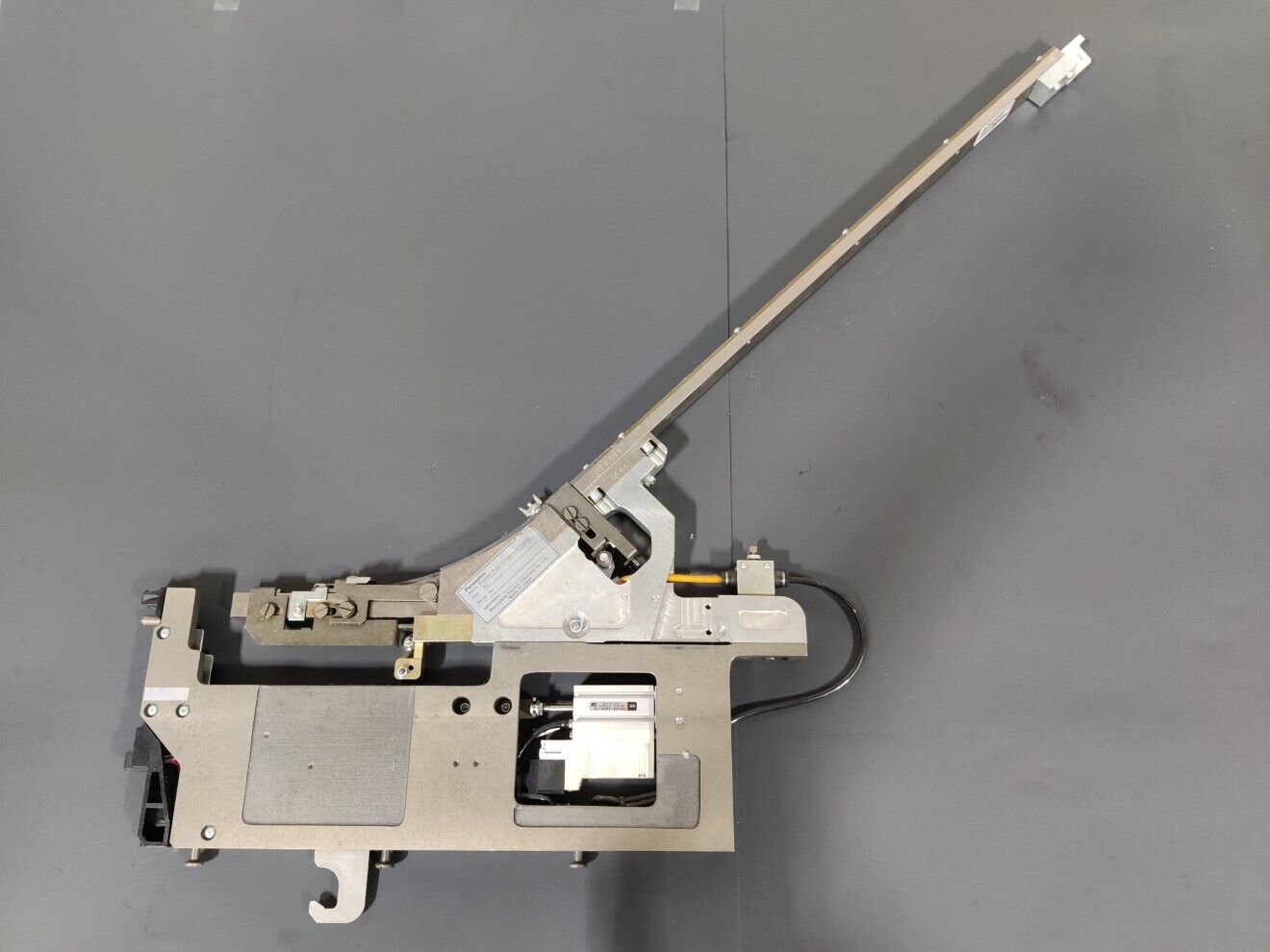

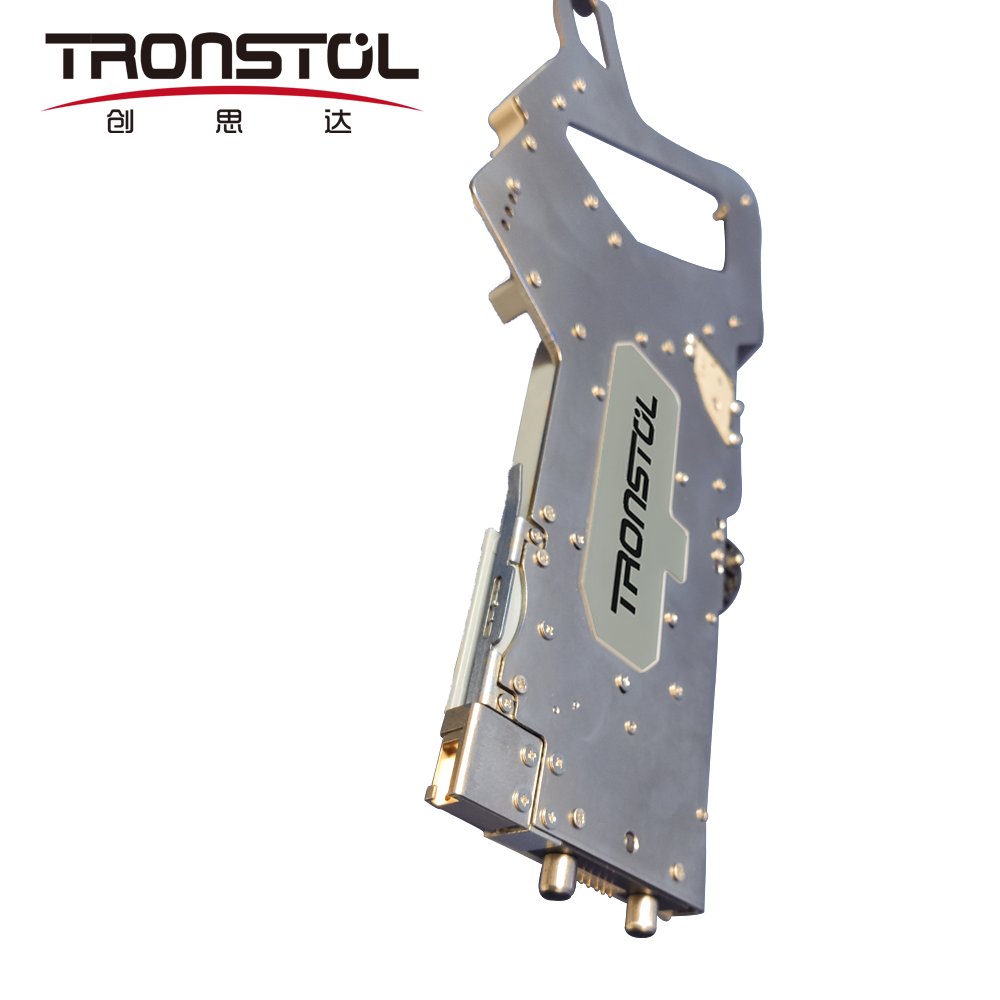

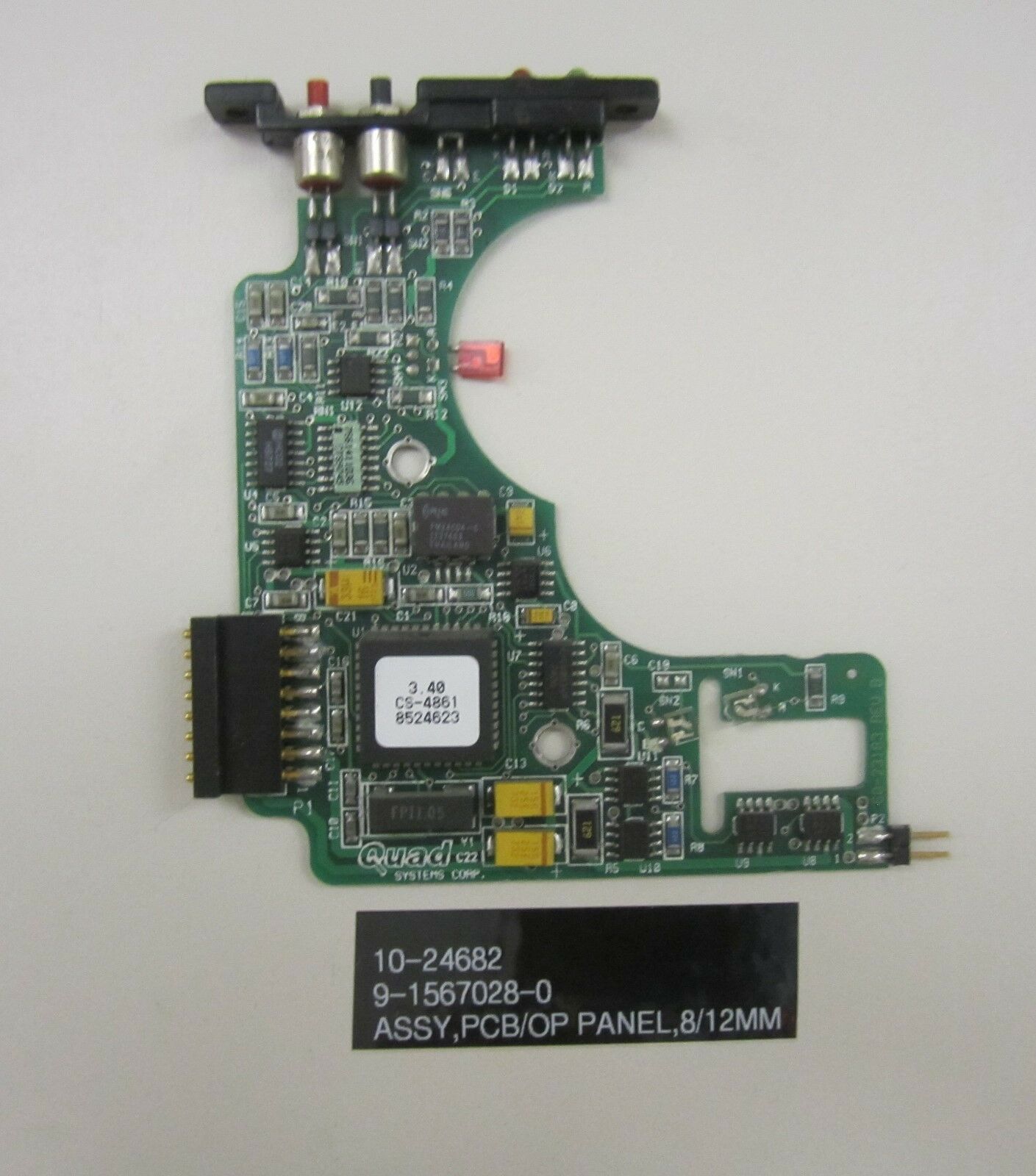

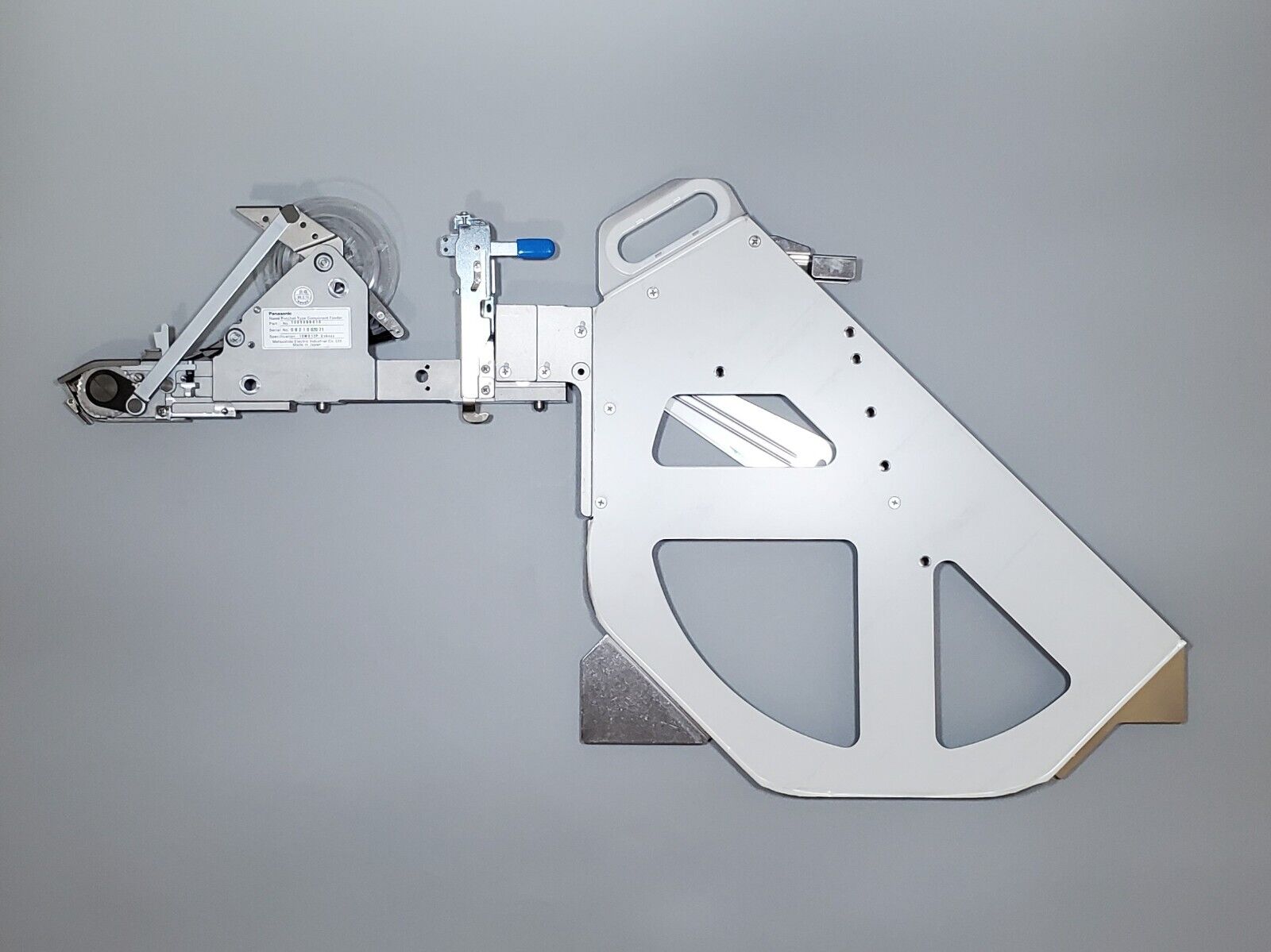

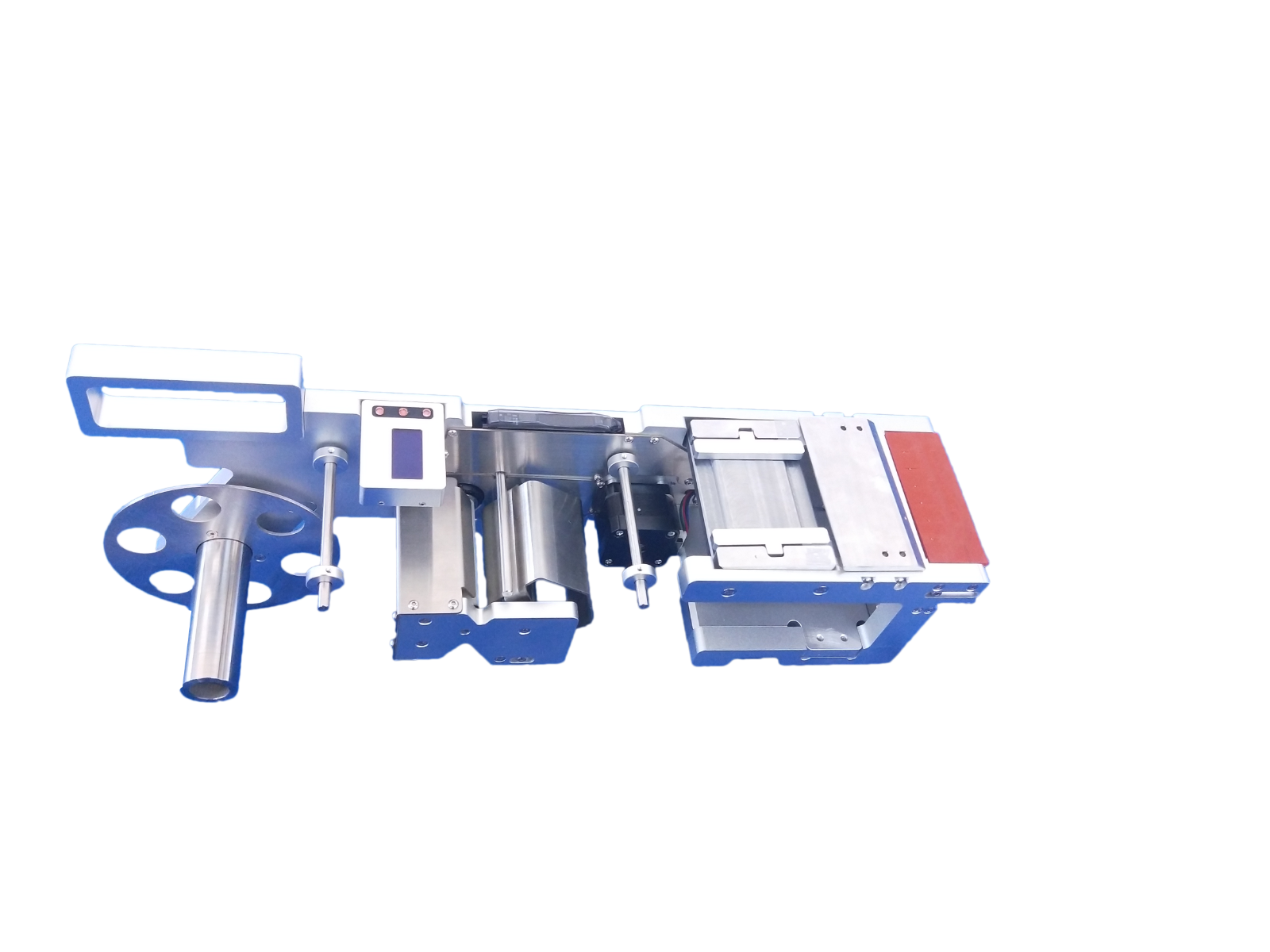

These is a custom designed and custom 3D printed replacement tape peeler upgrade roller pair for the Tyco / PPM Quad series 12mm feeder units. Tired of the tacky, gummy, broken and worn out friction rollers in your Tyco / PPM Quad feeders causing manufacturing delays? Tired of the 3D printed friction rollers being too slippery to properly grab the tape? This item is perfect for you! The indexing motor can almost be stalled by holding onto the tape, say goodbye to tape peeling problems! This includes 2 upgrade gear rollers, enough to repair 1 8mm feeder. These will work with both IQ and non-IQ standard feeders. Please keep in mind, you will need to replace the urethane friction roller and the pressure roller with these new tape peeler rollers. Any friction rollers that have melted down due to heat and humidity that have any residue left behind would need to be cleaned off with isopropyl alcohol as to prevent gumming up the new tape peeler rollers.**Due to concern about slop on the D-Shaft, this item has been updated to include a drill location for the set screw that is with the factory OEM friction roller. We do not drill this out but using a #43 twist drill bit and a #4-40NC tap, the OEM set screw can be moved over to the new drive gear. There are some non-OEM friction rollers out there that use a different threaded set screw than #4-40. If a set screw is required, any #4-40 1/8" set screw should work ok and those can be picked up at most fastener hardware suppliers.**

Please note, this listing is for the tape peeler rollers only, the feeders and other items in the pictures are for reference only. Shipping is first class mail for free but can be upgraded to priority at the customer's expense. These are 3D printed using FDM and the process isn't perfect. There may be minor defects such as waves, "burns" or "strings" that should not affect the performance of these upgrade units. The product will look layered, but that is how FDM works. We do guarantee that they will be free of defects that would prevent them from working though. The rollers may have a tight fit, do not force them, just use a reamer or a small file to gently open up the holes and they should slide into place without any issues.

The fit on the D-Shaft will feel sloppy. This is by design due to fit issues that I have run into where the D-Shaft has been deformed by an overtight set screw. This slop has not caused any issues on the units I have installed thus far.

Please contact us for questions or for large orders as they do take time to print.

As this is a common question we receive on this product:

We are a husband and wife team. The husband works for a small automation electronics company which has an SMT line with 4 total SMT assemblers. 2 Mirae 1025B6 units, a Quad QSP-2 and a Quad QSV-1. These gear upgrades were designed due to the issues they have with the Quad assemblers. Just for further reference there is also an MPM Accuflex stencil printer and a Heller 1912 reflow oven.